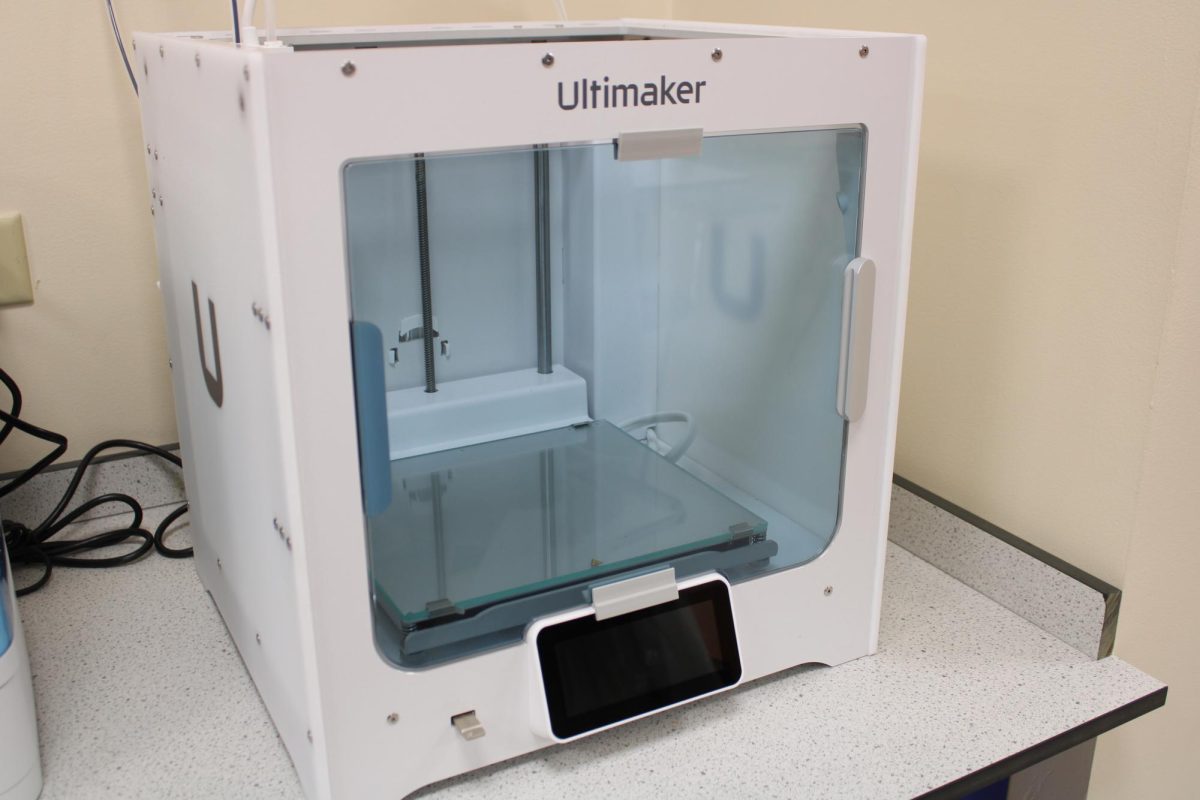

It’s no secret that the world we live in is rapidly progressing beyond our wildest dreams of even just a few years ago. From generative AI to the first successful brain chip implant only a few days ago, it seems that every day a new technological breakthrough sends us further into the future in leaps and bounds. Among the many exciting developments is that of 3D printing (also called additive manufacturing). Like many other advancements, the idea of quickly printing complex objects in your home was merely a pipedream only a matter of decades ago. Nowadays, the technology is so ubiquitous that even Good Counsel’s STEM lab has several on hand. But how did we get here? What even is 3D printing? And where is it going from here?

The first mention of a device like a 3D printer appears in the 1945 short story “Things Pass By” by Murray Leinster. However, the first practical device resembling 3D printing, the Liquid Metal Recorder, was only patented in 1971. The term “3D printing” itself was only coined in 1993. Further development continued through the 1980s. However, like any other form of cutting-edge technology like a computer, the printers were prohibitively expensive and mainly limited to large manufacturing and research operations. Only in the late 2000s into the modern day, with the rise of the internet making it possible for prospective users to collaborate and share software, has 3D printing become accessible for average people, with the price per printer falling to just around 300 dollars.

But how does 3D printing work exactly? In modern printing, the first step is to make a virtual model of the object to be printed using digital software, creating a printable file. The file is then effectively “sliced” into hundreds or thousands of layers, into which the printer precisely places material (usually semi-liquid plastic or metal). This process is repeated until every layer is filled, creating the finished product.

This technology, which can precisely replicate just about any object that can be modeled, is now being put to use in numerous industries. Among the most notable examples, in the medical field, 3D printing can be used to make dental products, models of patients’ anatomy for surgeons to practice on before operations, and even full prosthetics that are more durable and cheaper than traditional ones. 3D printing is also useful for businesses to quickly create accurate prototypes of their products, and it can be used to quickly manufacture small batches of products. Automotive makers have adopted the technology to create parts for their newest cars, and hobby mechanics use it to make parts to restore vintage cars. The technology has so many applications for the air and space industries that a metal 3D printer is currently on the way to the ISS, to help astronauts produce the spare parts they need in space. 3D printing is an exciting field to be in right now, and it’s worth keeping an eye on to see where it goes next!

Sources:

What is 3D Printing? 3D Printing.Com. https://3dprinting.com/what-is-3d-printing/

GCFGlobal (n.d.). The Now: What is 3D Printing? Retrieved January 31, 2024, from https://edu.gcfglobal.org/en/thenow/what-is-3d-printing/1/

Airbus (2024, January 31). The world’s first metal 3D printer for space is on its way to the ISS. Airbus.com. Retrieved January 31, 2024, from https://www.airbus.com/en/newsroom/stories/2024-01-the-worlds-first-metal-3d-printer-for-space-is-on-its-way-to-the-iss